Our Solutions

Conax designed a dual-seal thermocouple to save production load when thermocouple...

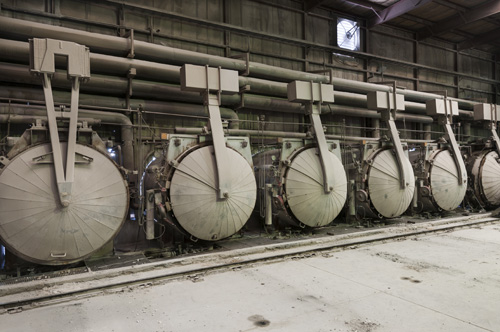

Conax designs an adjustable multi-point thermocouple for furnace while under...

The Problem: Liquid Natural Gas requires a lot of power for...

Conax introduces a patented coating that extends the life of...

Conax provides an instrument manufacturer with a Hazardous Location (HL) seal...

Conax develops a leak-proof compression seal fitting (sealing gland) for feedthroughs...

Conax provides a Molybdenum sheathed thermocouple with an internal design...

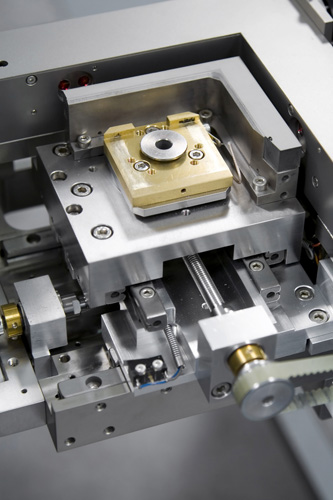

Conax develops a solution that prevents vacuum leakage which could...

Conax develops a customized insulated seal fitting to meet a client's precise...

Conax designs a multi-hole compression seal fitting/flange for easy replacement...

Conax engineers an electrode that results in a more robust...

Conax engineered a high-quality, low-maintenance thermocouple for the ASM®‡ EPSILON®‡ Reactor that helps our customers...

A spring-loaded thermocouple helps keep tips in contact with the...

Conax developed a single-point calibration thermocouple to allow monitoring of...

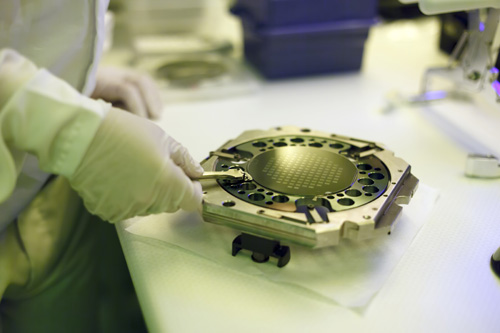

A multi-hole fiber optic vacuum feedthrough allows precise control for stage in...

The Conax triple-point calibration thermocouple saves time and maintenance costs...

Conax 3-zone and 5-zone profile thermocouples offer the ideal balance between a...

Conax helps engineer a custom sensor design that can withstand liquid motion forces...

Conax engineered an 8 AWG Type K thermocouple with a...

Conax developed a reusable MHM gland with Viton sealant to...

Conax provided in-process RTD sensors which increased efficiency and reduced delamination....

Conax provided a severe duty cast iron pipe clamp thermocouple...

Conax designed a PTFE sleeve within a thermocouple sheath to...

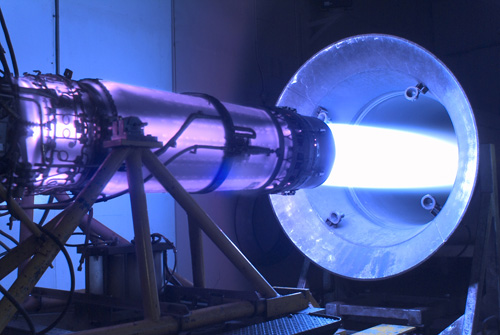

Conax's Haynes® 188, a cobalt-base alloy, offers high temperature strength and...

Conax designed a special sealing gland with a recessed pocket...

Conax designed a flexible Type K PTFE-jacketed cable with stranded...

Conax provided Hazardous Location seal fittings for simple installation on...

Conax designed an extremely rugged mineral insulated cable assembly with...

Conax provided a variety of thermocouple lengths to cover the...

Conax created a unique, reliable integral port design, eliminating potential...

Conax provided a custom-designed hybrid of its EG feedthrough allowing...

Company: Petrochemical Refinery Challenge: A refinery needed a way to seal a...

Industry: Oil Refining Application: Fluid Catalytic Cracker Unit Customer Requirement: Catalytic...

Industry: Petrochemical Application: Deep Gas Wells Customer Requirement: This customer needed...

Industry: Pharmaceutical Application: Monitoring internal chamber and product temperatures up...

Company: Pharmaceutical Challenge: An RTD assembly was needed to monitor...

Conax Technologies solves a leakage problem a customer was experiencing...

Customer Requirement The production of eye drops requires periodic sterilization...

Challenge: A previous supplier's extended life thermocouple assembly exhibited poor quality and...

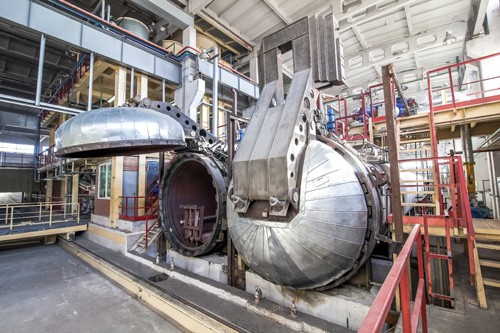

Application: Monitoring process temperature in vacuum up to 1300°C in a...

Customer Requirement: This design was created for an end user of...

Customer Requirement: Our customer is an equipment manufacturer (OEM) in the...

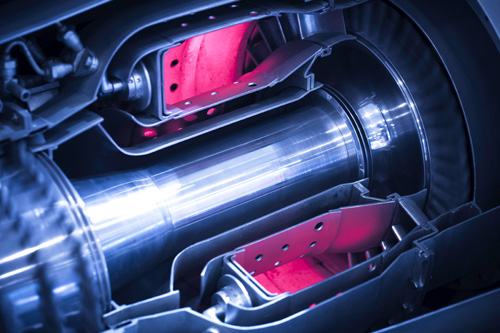

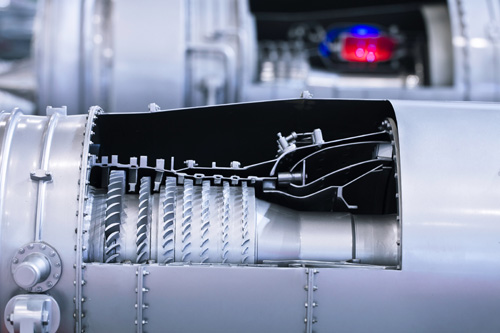

Company: Power Plant Challenge: A power plant has installed a Frame 7E...

Challenge: A Conax customer needed a source for flashback thermocouples...

Company: A major steel company in the U.S. Challenge: The customer...