Introducing LeakDefender™ Brand Thermocouples

LeakDefender™ Brand Thermocouples

Real-time gas monitoring to minimize wafer loss and maximize thermocouple life

LeakDefender™ Brand Thermocouple benefits

- Lower tool Cost of Ownership (CoO): Real-time leak detection ensures faster leak discovery, limiting loss to a single wafer.

- Improved yield: Surface defects caused by leaks are reduced to minimize scrap wafers.

- Reduced process variation: Atmospheric leaks that cause excessive chamber coating and power disruption are prevented, reducing the need for adjustments to power offsets.

- Reduction in unscheduled downtime: Early detection of atmospheric leaks prevents premature chamber cleans.

- Increased tool and cleanroom safety: Localized leak detection occurs earlier than with cleanroom H2 detectors, preventing hydrogen chloride leaks from corroding external hardware.

- Seamless integration with system controller: Thermocouples connect directly to OEM-provided user digital input.

- Proven technology: Hydrogen gas detectors are widely used in the EPSILON®‡ H2 monitoring system.

- ‡ ASM® and EPSILON® are registered trademarks of ASM International. Neither Conax Technologies nor its products are affiliated with, licensed, approved by or sponsored by ASM International.

- One-shift installation: The 6-hour installation and 2-hour calibration and testing can be completed in a single day.

- Cost-effective protection: The cost is less than a single scrapped device wafer, and off-the-shelf components eliminate the need for special equipment.

- Center TC monitoring: The center TC is most prone to premature sheath failure. The LeakDefender™ Brand Center TC monitoring line leaves the rotating assembly through a special slip ring assembly.

How it works

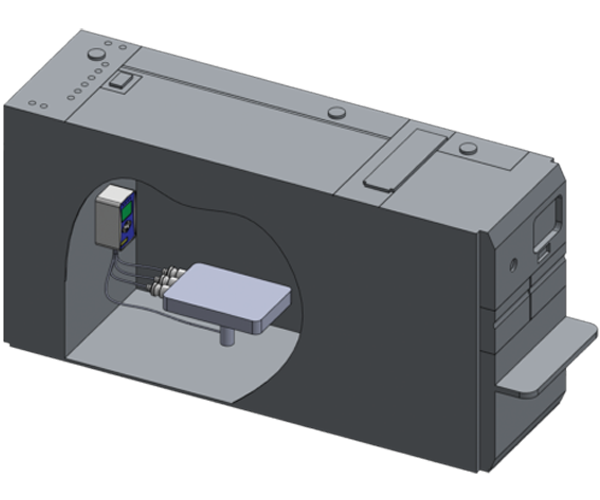

Depending on process chamber type, a typical reactor has two or three LeakDefender™ thermocouples installed in the horizontal orientation and one LeakDefender™ center thermocouple installed in the vertical orientation.

Gas monitoring lines exit each of the LeakDefender™ thermocouples and are routed into the TC Sentry System™ gas monitor. If a premature thermocouple sheath breach condition occurs, this in-situ monitoring system will detect the leak and prevent product loss and major unplanned maintenance events.

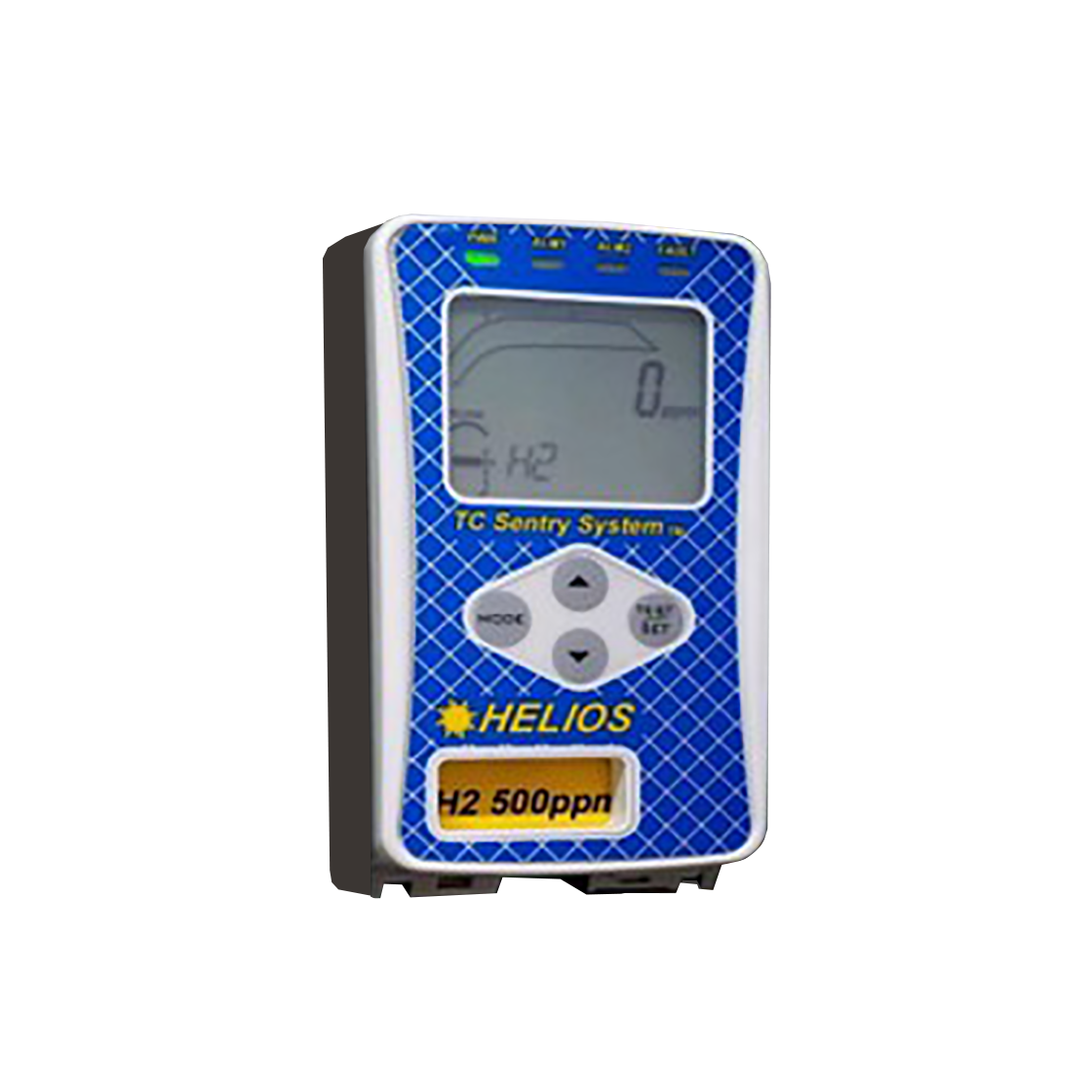

About the TC Sentry System™ gas monitor

The TC Sentry System™ gas monitor is manufactured by Helios Technical Services. This system is capable of detecting minute volumes of hydrogen and triggering one or more control outputs. The ultra-fast detection and response of the system will prevent product loss and contamination of items internal to the process chamber. Detecting a single premature thermocouple sheath failure can save significant time and money.