A multi-hole fiber optic vacuum feedthrough allows precise control for stage in a vacuum environment.

Company: Laser Interferometer Manufacturer

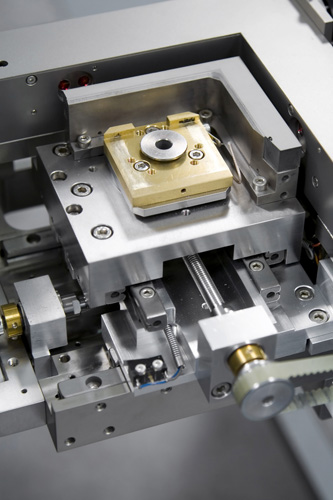

Challenge: Interferometers are used to accurately control stage movement for the proper positioning of the wafer and reticle stages relative to each other. As node sizes continue to shrink, this Conax customer was faced with manufacturing precise controls for stage movement. Because certain photolithography tools have stage in a vacuum environment, a laser beam needed to be introduced into and out of the evacuated stage area through fiber optic cables.

Solution: Conax offered a multi-hole feedthrough to allow multiple fibers to be fed through a single flanged connection. Each fiber is sealed inside a stainless steel tube and the tube is subsequently sealed in the compression fitting. This method allows a high vacuum seal while inducing a low dB loss based on the seal.

Impact: The Conax fiber optic vacuum feedthrough allows more signals to be used from a single laser input, maintaining precision and increasing quality control.