Oil and Gas

Solutions for the Oil and Gas Industry

Leading the way with innovative ideas

Custom-designed solutions

For over 70 years, Conax has designed and manufactured compression seal fittings, temperature sensors and cable and harness assemblies for a broad range of industries, including applications across the Oil and Gas industry. Our innovative designs span the upstream, midstream and downstream sectors of the oil and gas industry.

The ideas for our custom-designed solutions are the result of strong partnerships. We listen to our customers and work with them to engineer customized solutions for every challenge they face. We’ve helped our customers in the Oil and Gas industry with:

- R&D and measurement

- Exploration and extraction, including downhole instrumentation, well-head, and surface applications that ensure safety and efficiency performance metrics

- Pipeline and transmission

- Waste energy cogeneration

- Refining, processing and distribution

- CNG, LNG and cryogenic storage

Sample Probe Assemblies

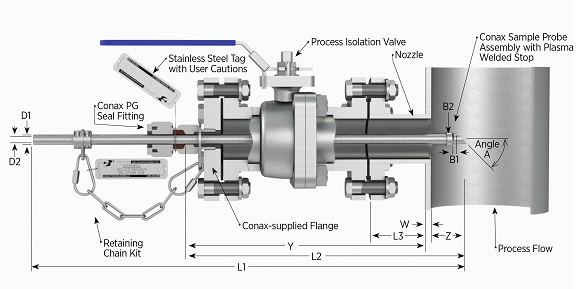

Conax Technologies’ Sample Probe Assemblies (SPA) are used to insert and retract an analyzer sample probe or injection quill into a pressurized process through a process isolation valve. Conax SPAs are designed for unique applications, including: process analysis, flare stack emissions, hot tapping liquid or gas streams, and more. Conax features include:

- Plasma welded stop collar

- Retaining Chain Kit

- Wake frequency calculations

- Various probe ends and valve types available

If you need engineering help to ensure you’re choosing the proper SPA for a specific application, we’ve created the Wake Frequency Solution Builder™ to generate immediate, online wake frequency calculations. This tool enables you to enter data for the specific SPA you need and receive immediate calculation results, based on ASME PTC 19.3 TW-2010 and/or IEC/TR 61831 standards. If there are problems with the configuration of your SPA, you’ll see exactly what needs to be adjusted. If the design is approved, you’ll see confirmation that each element tested has passed, and you can contact us to purchase the SPA.

Explosion-proof rated Ex/MBS Series miniature bearing sensors

The bearings of rotating equipment operate in arduous conditions, and the seals in typical sensors can break down over time, leading to oil leaking and wicking. This results in the potential for oil to ignite and catastrophic failure to occur at the junction box and surrounding area.

Conax Technologies’ Ex/MBS Series explosion-proof rated miniature bearing sensors are your NEVER-FAIL solution. Specially designed to excel in harsh environments where typical miniature bearing sensors fall short, these sensors utilize a proprietary redundant sealing process that eliminates the risk of oil leaking and wicking. Our Ex/MBS Series sensors have received the most stringent certifications, assuring they’re safe in explosive atmospheres. View a demo here.

Seals and sensors for the Oil and Gas industry

Upstream: Exploration, Extraction and R&D

- – Conax SPGA and DSPGA Multi-hole Split Compression Seal Fittings—Our first multi-hole split seal fittings that carry both hydraulic and pneumatic catalog pressure ratings. SPGA assemblies seal on multiple elements with a single split; DSPGA assemblies seal on multiple elements with a double split. The amount of pressure transmitted from the cap to the load-bearing washer, follower, sealant, and seat set is higher with our SPGA and DSPGA fittings. This creates higher sealing pressures that result in a tighter seal on the fitting body and elements.

- Hazardous Location (HL) Compression Seal Fitting—Conax Technologies’ HL Compression Seal Fittings are designed for protection in a wide variety of hazardous environments. The Conax HL Fitting is pressure rated to 500 PSIg and has been CSA® certified in the U.S. and Canada for use in hazardous locations defined by the NEC® as Class I, Div. 1 and 2, Groups B, C, and D; Class II, Div. 1 and 2, Groups E, F, and G; and Class III.

- High Density (HD) Feedthroughs—Conax Technologies’ HD Series high density mechanically sealed feedthrough assemblies allow multiple insulated wires to be installed through a single port. These assemblies consist of a stainless steel tube swaged over bundled 24 AWG solid Teflon-insulated thermocouple wire or copper wires. The thermocouple pairs are available with or without junctions. HD assemblies provide an excellent means to pass numerous thermocouple, RTD and low voltage instrumentation wires through a vessel wall without breaching the wall in multiple locations.

- Multi-Hole Metal (MHM) Compression Seal Fittings—Conax MHM fittings can be customized to accommodate special hole patterns, irregular shapes and high density requirements. MHM fittings can be used to seal gradient thermocouple, RTD or thermistor probes, tube bundles, or a variety of devices within a single fitting. Our unique soft sealant technology seals against gases or liquids and resists element movement under pressure. Immersion lengths can be easily adjusted in the field. Individual elements can be set at different lengths to monitor multiple points.

- RTD & Thermocouple Assemblies for Hazardous Locations—Conax CBT 100, CBT 200, CBT 300 and CT 600 Series assemblies meet U.S. and Canadian standards (NRTL/C, CSA) for use in hazardous locations as defined by NEC Class 1, Division 1, Groups B, C & D; Class II, Groups E, F & G; and Class III.

– CBT 100 Series sensor-terminal head assemblies are available in all thermocouple calibrations and in RTD assemblies with 100, 200, 500 and 1000 ohm platinum, 10 ohm copper or 120 ohm nickel elements. Assemblies are available with stainless steel sheaths, a W8 mounting fitting and explosion-proof terminal head with terminal strip and 4-20mA transmitter.

– CBT 200 and CBT 300 assemblies are NEC-compliant replacement probes for use with UL and CSA-approved terminal heads in hazardous locations. CBT 200 provides a W8 fitting for attachment to the terminal head and to the vessel. CBT 300 provides a W7 fitting for attachment to the terminal head. A separate adjustable fitting is required to attach the probe to the vessel.

– CT 600 Series sensor-terminal head assemblies are available in all thermocouple calibrations and in RTD assemblies with 100, 200, 500 and 1000 ohm platinum, 10 ohm copper or 120 ohm nickel elements. Assemblies are available with stainless steel or Inconel sheaths, a spring loaded mounting fitting (CSLW) and explosion-proof terminal head with terminal strip.

Downstream: Refining, Distribution and Storage

- Direct Immersion Grounded Junction Thermocouples—Conax Technologies has developed and tested a direct immersion, 1/8″ diameter grounded junction thermocouple design for operating pressures to 40,000 PSIg. Units have been proof pressure tested to 60,000 PSIg at room temperature. This design uses an economical proprietary method of silver brazing a high pressure fitting directly to the thermocouple sheath. Testing concluded that the thermocouple’s calibration (Type J Thermocouple) was maintained after silver brazing and pressure testing.

- Sample Probe Assemblies—Conax Technologies’ Sample Probe Assembly (SPA) is used to insert and retract an analyzer sample probe or injection quill into a pressurized process through a process isolation valve. Ideal for unique applications such as process analyzing, flare stack emissions, or hot tapping liquid or gas streams.

- Temperature Sensors with Thermowells—Thermowells are pressure-tight receptacles that extend the life of a temperature sensor in environments where the sensor is not chemically compatible with the process media or the sensor does not have the mechanical strength to withstand the process flow or pressure. Thermowells also facilitate removing, changing, checking or replacing sensors without draining the process system. The use of standardized thermowells throughout a plant permits easy relocation of sensors.