Conax Technologies is excited to announce the launch of our Ex/MBS Series explosion-proof rated miniature bearing sensors. Our exclusive redundant seal technology raises the bar for safety, performance and reliability in demanding rotary equipment applications.

Your NEVER-FAIL solution

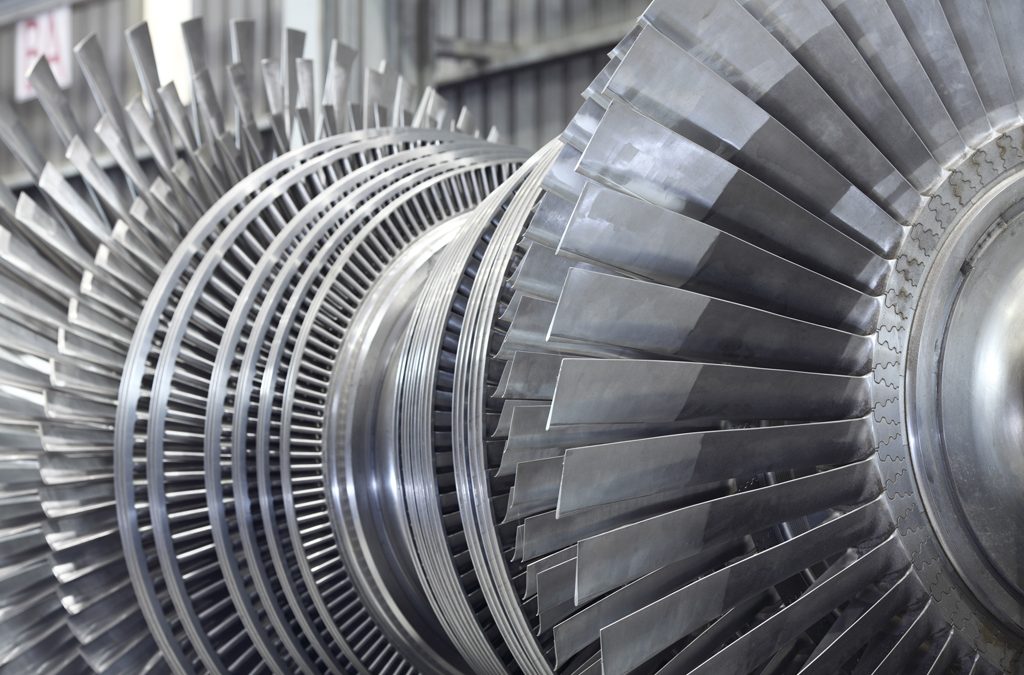

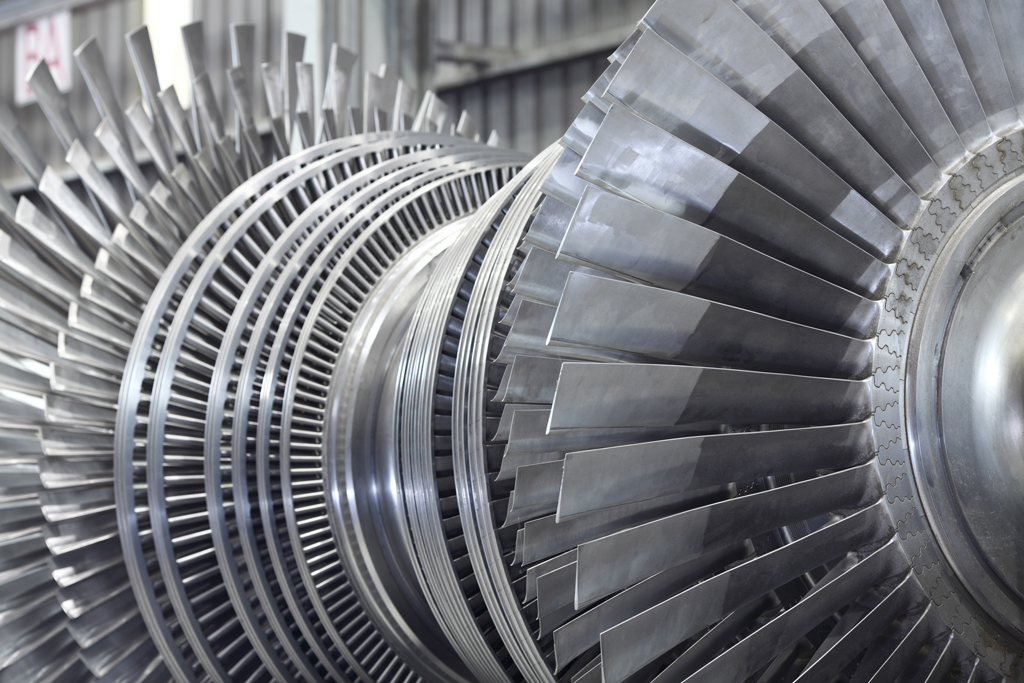

The bearings of rotating equipment operate in arduous conditions, and the seals in typical sensors can break down over time, leading to oil leaking and wicking that results in the potential for oil to ignite and catastrophic failure to occur at the junction box and surrounding area.

Our Ex/MBS Series sensors are specifically designed to excel in these harsh environments where typical miniature bearing sensors fall short. The sensors utilize a proprietary redundant sealing process that eliminates the risk of oil leaking and wicking to create your NEVER-FAIL solution.

See it in action here.

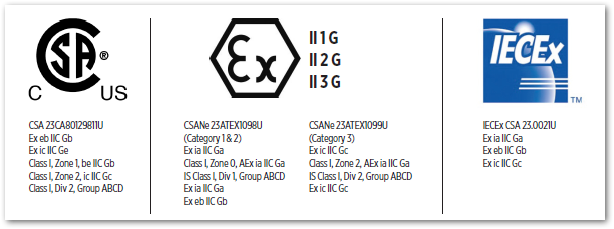

Certifications for Conax explosion-proof rated Ex/MBS sensors

Conax Technologies’ explosion-proof rated Ex/MBS Series sensors have received the most stringent certifications, assuring they’re safe in explosive atmospheres.

Benefits you can count on

Ex/MBS Series sensors offer a multitude of benefits for rotating equipment applications in challenging environments:

- Reduced downtime: The superior reliability of the Ex/MBS Series sensors ensure highly reliable temperature monitoring to virtually eliminate equipment shutdown due to a failed bearing temperature sensor and minimize costly downtime.

- Enhanced safety: The exclusive redundant sealing technology safeguards against oil leaking into the junction box, promoting operational safety and reducing the risk of accidents.

- Proven reliability: One major turbine manufacturer has used Conax Technologies’ miniature bearing sensors exclusively since 2003, and the sensors have never failed.

Discover the advantages our Ex/MBS explosion-proof rated sensors

Ex/MBS miniature bearing sensors are used in rotating equipment applications in a variety of industries, including power turbines, water treatment, oil refineries, and more. To learn more about our never-fail solution and how it can elevate your application performance, click here.